/ Demo case 2: Glass production /

Steklarna HRASTNIK is an innovative manufacturer of premium glass products. Glass production is an energy intensive process where 75-85% of the total energy is spent for heating of raw materials or waste glass in the glass melting furnace to more than 1500°C running continuously through its entire lifetime (approx. 8-10 years). Europe’s glass industry primary operates end fired furnaces which use both gas and electricity (<10 electricity share). This process will be replaced with a first-of-a-kind hybrid end-fired regenerative furnace with a more than 40% electrical melting share. In the CITADEL project a hybrid end fired furnace will be upgraded to increase the share of electric power from 40% up to 70%. A specific objective of this demo case is to use the large reservoir of molten glass as an energy storage by coupling the furnace with a rooftop photovoltaic (PV) power plant. The glass melt will be overheated in periods when a supply of solar electricity is available at favourable prices.

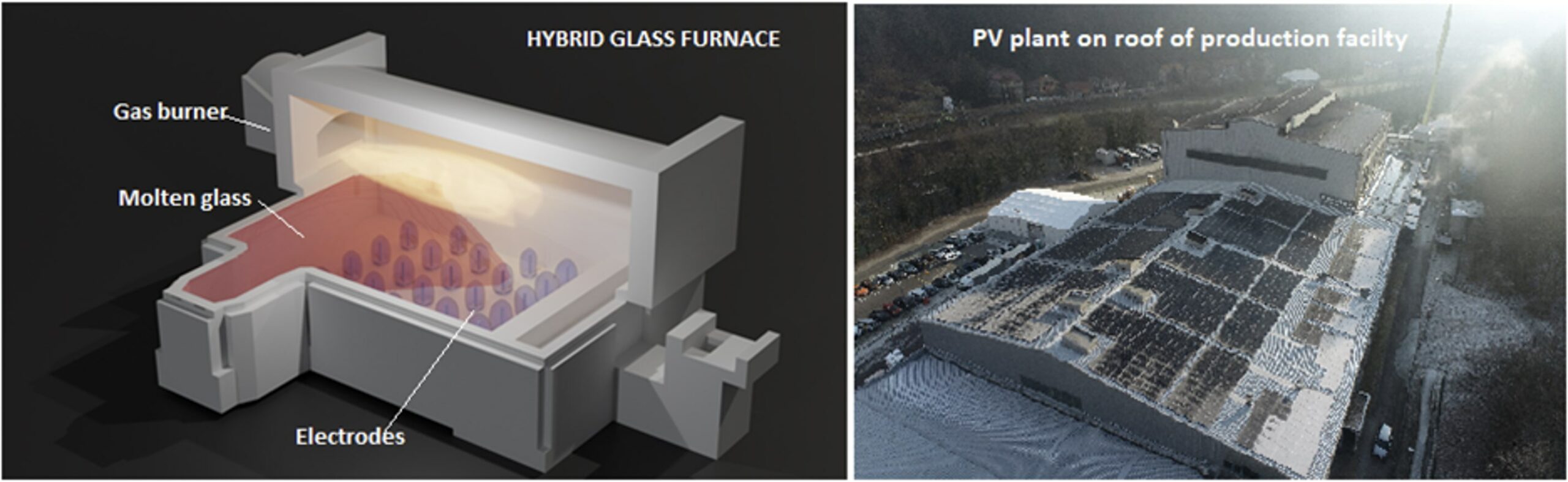

Figure 2: Demo site: (a) Hybrid regenerative furnace; (b) local RES generation unit.